A "gap analysis" approach to help you manage improvement wisely

Applying decades of Root Cause Analysis experience to establish a documented process

Focus on root causes instead of symptoms and eliminate repeated failure

RCA Consultancy

Expert RCA services for identifying Root Causes and designing effective solutions to eliminating repeated failures

Our expert Root Cause Analysis solution will assure the plant and process achieve the desired transformational outcomes including no safety incidents, no repeated failures, high plant availability, an informed and equipped workforce, and problem-solving culture.

Get insights and guidance on how you can improve your plant bottlenecks and bad actors from experts who have decades of experience working with world-leading operating companies.

The better case in achieving excellence through facilitated RCA approach

Identify GAPs by Conducting Assessment

Our unique approach will help you understand your current state and provides a roadmap for improvements that yield the biggest impact on your investment.

Professional RCA Investigation Services

Our team has 20+ years of hands-on experience in conducting RCA investigations that yield deep benefits.

Getting an Expert Support Prompt Like Never Before

Many projects can be completed quickly and without an on-site visit.

Proven knowledge and Industrial Experience

Our team-based approach combined with decades of industry experience, allows us to understand your problem, culture and communicate in your language while ensuring the appropriate expertise is applied to your RCA needs.

Highly Efficient and Flexible

We are structured to accommodate RCA requests of any size or complexity, from short mentoring to multiple experts at your site for an extended period to conduct any minor or major RCA investigation.

RCA Consultancy Services

Discover how we help numerous companies achieve their desired plant availability and reliability by eliminating repeated failures.

Root Cause Analysis Assessment

Our RCA GAP assessment follows a combination of qualitative and quantitative approaches in identifying gaps and developing solutions to establish a best-in-class root cause analysis program backed with problem-solving and prevention control culture.

Root Cause Analysis Procedure Development

Having an effective procedure that is accurate, meaningful, and brief is not always easy. But, with assistance from an expert and knowledgeable RCA practitioner, your can review your existing procedure, identify great opportunities, and develop a practical procedure to improve the RCA effectiveness across the organization.

Root Cause Analysis Investigation

Get our expert investigation service to conduct and facilitate a full-fledged root cause analysis investigation to identify root causes and develop a solution for your failed or underperforming assets as well as incidents related to Health, Environment, and Safety.

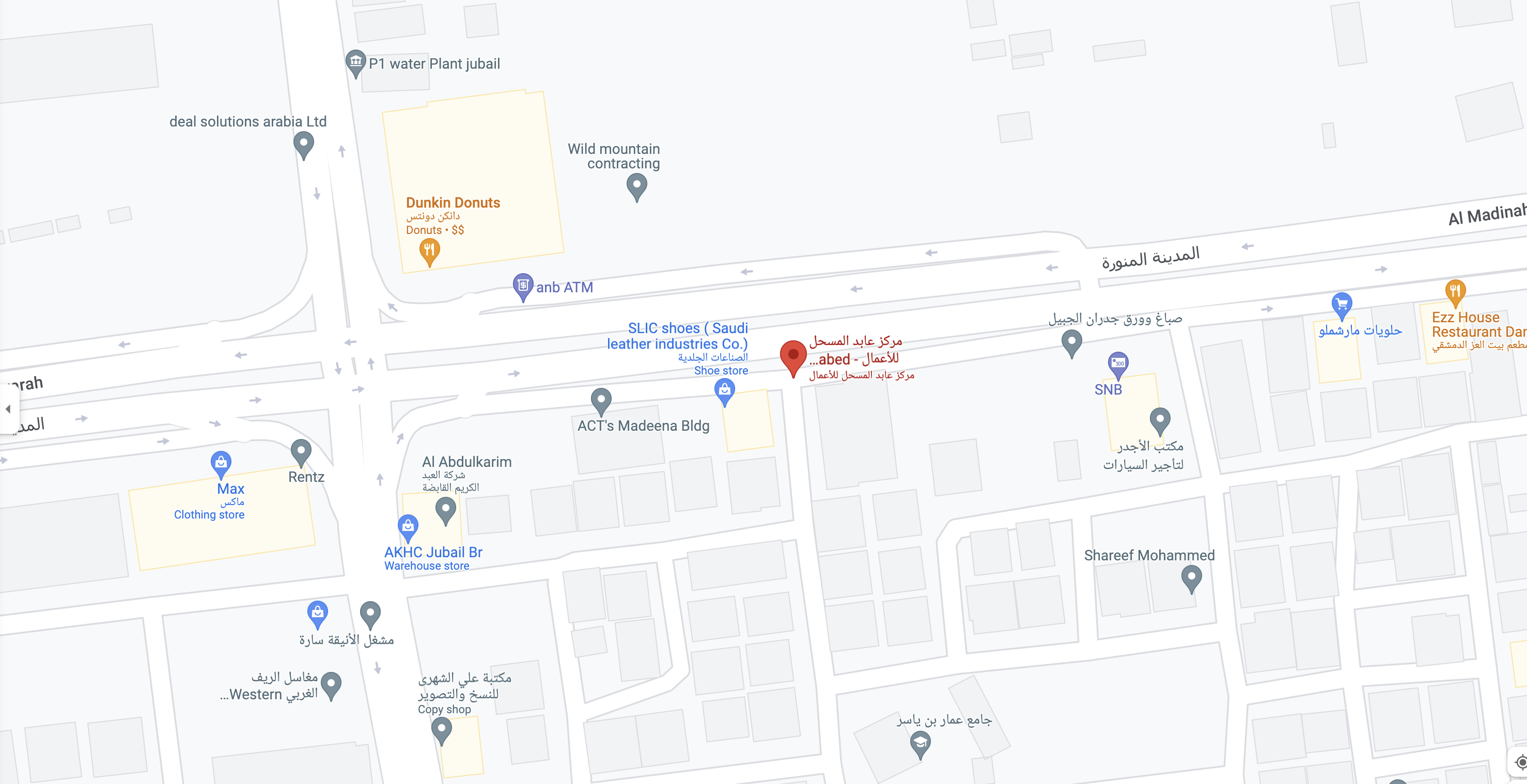

Our Valuable Customers

I attended a Lubrication training and certification through REC, and it was very well-organized, knowledgeable lubrication training, and passed my MLT exam.

Since 2009, we never hesitated to request REC to provide us with RCA, Reliability & Safety trainings because we always get positive feedback from our attendees. All REC trainers are very-well knowledgeable of our process, plants, and procedures.

REC is very responsible, goal-oriented, and very-organized when it comes to customer service. We have completed an RCA investigation on a failed equipment with their electrical expert, and received a well-written and valuable RCA report. Now we are considering to enhance the culture of RCA in the organization with REC.

A complete Reliability & HAZOP programs that consist of software, training & case studies were delivered during COVID-19 pandemic periods. REC were careful and thoughtful to accept the challenges, and they never disappoint us.

A complete Reliability & HAZOP programs that consist of software, training & case studies were delivered during COVID-19 pandemic periods. REC were careful and thoughtful to accept the challenges, and they never disappoint us.

We had so many maintenance activities, but after utilizing RCM++, and improved the maintenance management systems.

RCA training was one of the best training we took, simply everything was perfect !

We had a class-A incident in one of our plants, and we realized it requires some expertise, so the first company we thought of to facilitate the RCA investigation was REC. They exceeded our expectations !

XFRACAS can easily report us on any safety/reliability incidents occurred to any of our assets.

We decided to go with REC in applying RCM & RBI software and methodologies because of the high ROI and their effective communication.

BlockSim is a user-friendly and powerful RAM software, which assists us in analyzing any system reliability, and can be incorporated with other ReliaSoft software packages.

Previous

Next