The Stakes Have Changed. Today’s Operating Environment Is Tough.

There’s pressure to simultaneously improve productivity and efficiency. Scrutiny from regulators and the public is higher than ever. In the digital age, closing-the-loop between Operations, Maintenance, Planning, Engineering, and HSE to get more work done safely and efficiently is no longer a nice to have. It’s the new standard. But turning strategic intent into operational reality on the ground isn’t easy.

By establishing consistent working practices and conditions, hazardous industry operators can improve their safety performance and prevent incidents. But, permit to work software must be fully integrated into Operational Risk Management architectures to produce real value, and that’s where most permit to work software falls short.

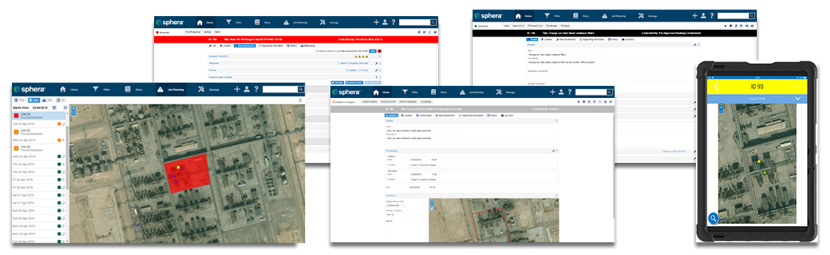

Manage activity with control in real-time, not in permit duration.

Now teams can operationalize the plan by bringing together all of the jobs, including safety dependencies, to build a truly executable work schedule.

Capture all activities and associated risks and display them in real-time dashboard views to easily see when and where they are occurring

Understand and manage SIMOPS and detect conflicts

Ensure work controls expose Major Accident Hazard (MAH) risk – not just permits and personal safety

Standardize and harmonize your policies into consistent operational practice

Increase productivity through pre-defined templates that incorporate best business practices related to worker safety

Your Journey to Operational Risk Management Starts Here

Sphera’s Permit to Work software delivers a single, shared view of the operational reality. It arms everyone with the right information at the right time so that they can make more informed, effective operational decisions. For a holistic, real-time view across an entire facility, Sphera’s solution combines information from permits, isolations, hazards, maintenance shifts, and SIMOPS.

The industry 4.0 technology integrates risk analysis across domains and through seamless integration with asset performance management software to deliver a real-time view of the operational reality and the ability to mitigate interdependent risks through the work permissions process.

Information about asset health, mechanical integrity, and equipment-related risk are accounted for in the context of potentially hazardous work activities. And maintenance work such as inspections, repairs, and preventative work are executed only after all safety measures are in place – whether it be a LOTO process, a hot work or fire protection measure, safe confined space entry, and more, to ensure a safe working environment.

Training Courses

Find training for life data analysis, accelerated life testing, and reliability growth with guided usage of Weibull++ software.

Events

Case Studies

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Our Valuable Customers