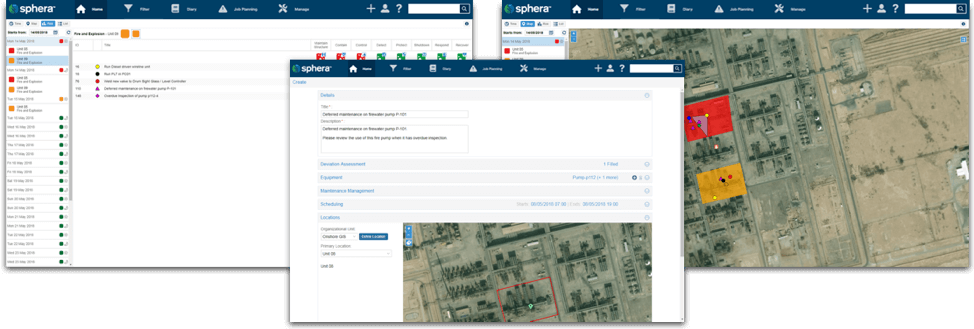

Since the day an asset becomes operational, its process safety risk exposure begins to change. Impairments, deferrals, overrides, Management of Change issues, the status of safety-critical equipment, or even how well processes and procedures are followed have a cumulative impact on Operational Risk. Unavoidably, risks are often managed in different parts of the organization.

Not having a clear view of all the factors that impact the operational reality results in operational inefficiencies, long wait times for frontline work teams, unplanned downtime, and the potential for process safety losses.

Hazards must be understood on a real-time basis, and the continuous state of process safety barriers is maintained as designed to reduce incidents.

Sphera’s Control of Work software delivers a single, shared view of the operational reality. It arms everyone with the right information at the right time so that they can make more informed, effective operational decisions. As part of the solution, Process Safety Barrier Management software is the first offering to connect all operational risks and display them in a dynamic barrier model that everyone can act upon. Connect the health status of process safety-critical equipment (SCE) sensor data, overdue and planned maintenance and inspection data, MoC, IoW deviations, and inspection data, emergency-critical, and environmental control system statuses to their cumulative risk impact. Calculate the potential Major Accident Hazard (MAH) risk exposure – like fires and explosions – present at the plant and area of the plant level.

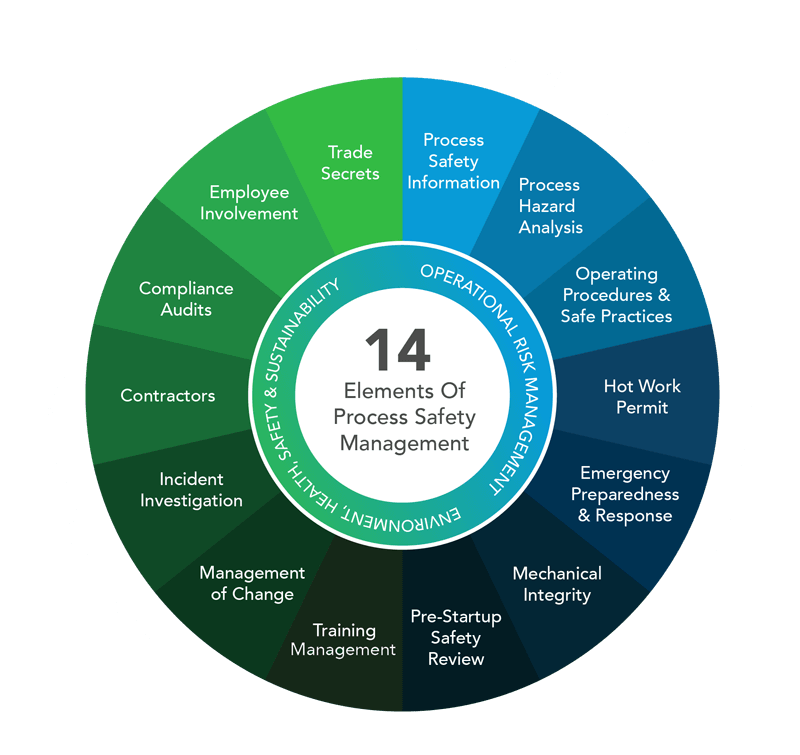

A Platform Approach for Aligning the 14 Elements of Process Safety Management

- Automatically bring all system, sensor, and human-derived inputs together in a joined-up way to see their cumulative risk impact

- Enable a collective understanding of operational risk at all levels of the organization

- See and understand the health of dynamic process safety barriers

- Access new leading indicators of risk that reflect the operational reality

- Make MAH risk exposure visible, prominent and available for all in real-time

- Proactively optimize the schedule to reduce risk

- Communicate risk insight and intelligence to all levels of the organization

Training Courses

Find training for life data analysis, accelerated life testing, and reliability growth with guided usage of Weibull++ software.

Events

Case Studies

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Our Valuable Customers