Industrial Digital Transformation

Heading

Some heading

some content

Some heading

some content

Some heading

some content

Some heading

some content

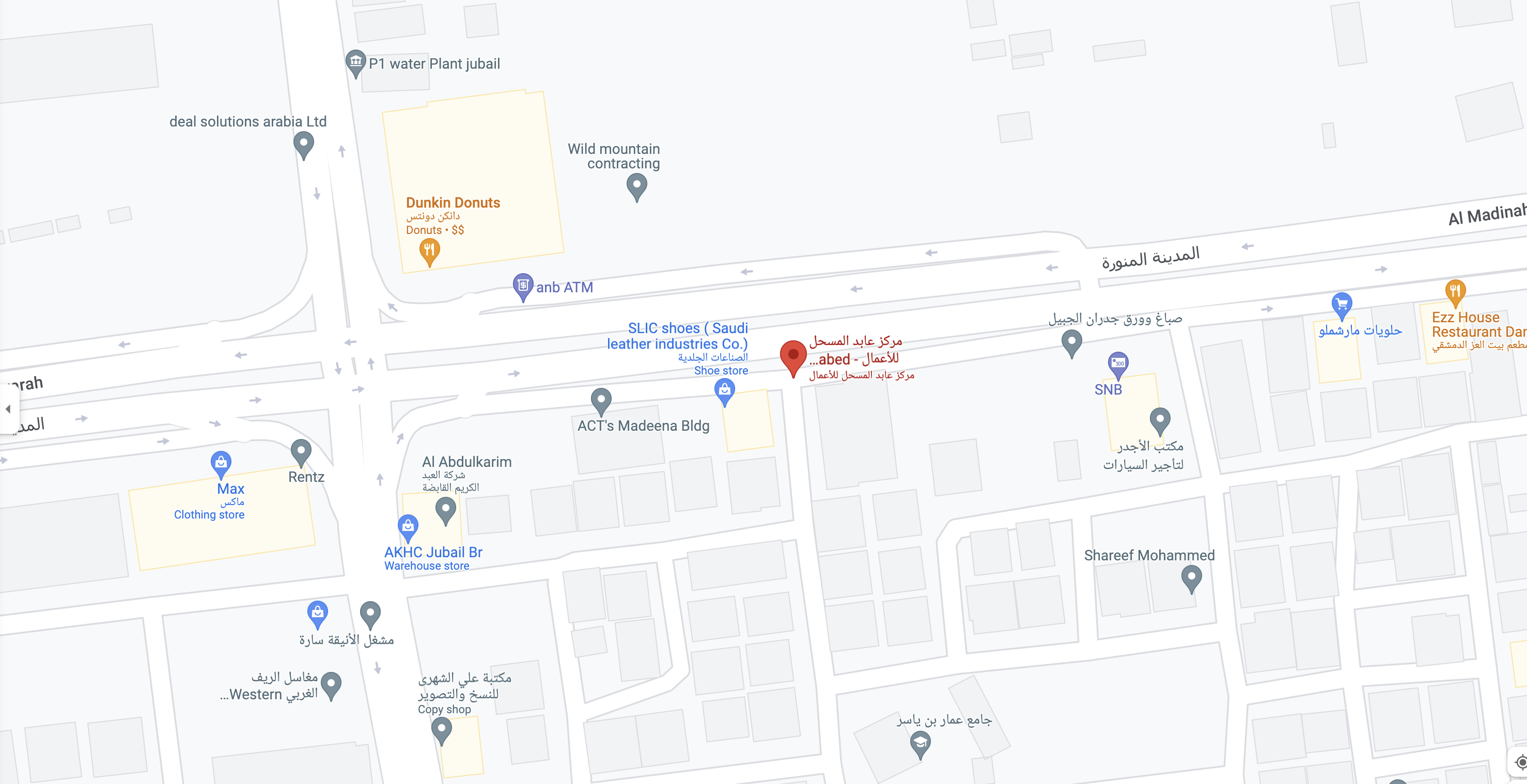

Antea Platform creates the ability to visualize Point Cloud rendering (digital twin) and a 3D model simultaneously, linked with the relevant P&ID’s and local maps.

Historically, 3D drawings were generated from construction drawings. In the recent past, we have imported them from 3D models created by the Engineering Companies. More recently have created them through 3D renderings made from Point Cloud data.

Resources

Discover how the implemented sustainability solutions will help shorten time to improve your brand and product

REC welcomes you to our blog!

Reliability Expert Center (REC) is excited to introduce to you our new website and blog. Here you will find biweekly submissions of featured articles concerning Reliability, Sustainability, Lubrication, & Inspection from local and global experts that offer industry insight and best practice methods.

Preventive Maintenance Won’t Solve Your Reliability Problems

There is a great deal that can be done to improve reliability outside of preventive maintenance. Some of it involves the maintenance department, and some of it does not.

Preventive Maintenance Won’t Solve Your Reliability Problems

There is a great deal that can be done to improve reliability outside of preventive maintenance. Some of it involves the maintenance department, and some of it does not.